Robotics and

Assembly Line Builders

industries

Robotics & Automation

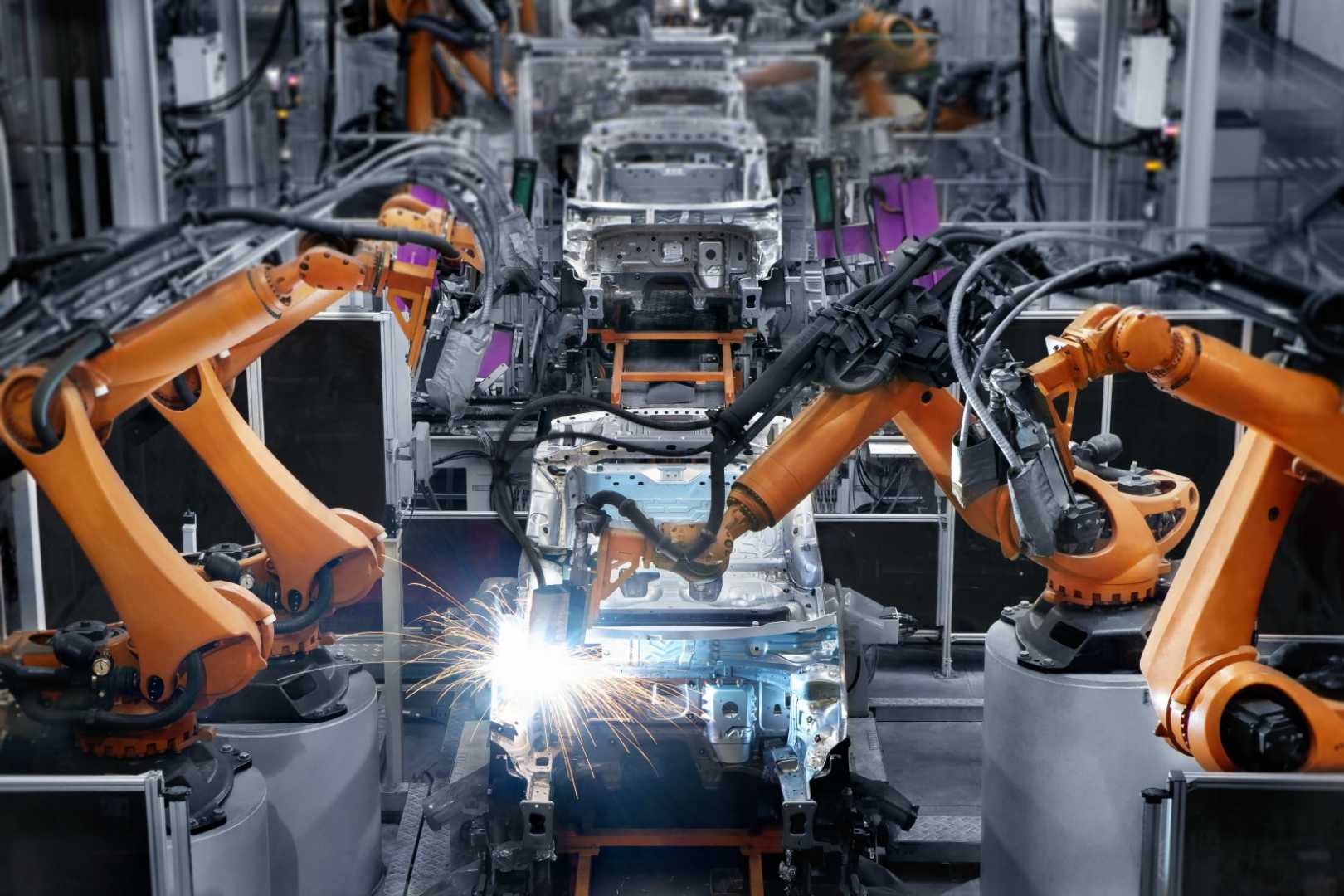

In diverse industries, manufacturers are driven by market demands and cost considerations to embed heightened automation and flexibility within their production sites. Each facility aims to expand product diversity, surpass quality benchmarks, and optimize its physical footprint. Embracing robotics and automation is crucial for managing intricate manufacturing processes, enhancing operational agility, and elevating production efficiency.

Robotics &

Automation Process

In various assembly stages, a combination of manuals and semiautomated procedures enable human-robot collaboration. The human role adds indispensable value, harnessing experience, intellect, and decision-making prowess. Simultaneously, robots’ repeatability enhances efficiency, curbing quality issues and mitigating failure costs associated with purely manual methods.

The emergence of collaborative robots marks a significant shift, obviating the requirement for safety barriers and infusing agility into intelligent tasks such as gap and flush inspection. Nonetheless, this manual process can prove both expensive and time-intensive.

Design, simulate and offline

program operations utilizing

robotics and automation

Tecnomatix offers robotics and automation programming solutions that facilitate the creation of robotic and automated production systems, accommodating both data-managed and file-based settings. These tools cater to diverse levels of robotic simulation and workstation development, spanning from individual robot stations to full-fledged production lines and zones.

Leveraging collaborative tools elevates interaction and alignment across manufacturing domains, fostering more intelligent decision-making and expediting the integration of automation systems with reduced errors.